Why Warm Transfer Fluid Is Very Important for Optimizing Energy Transfer in Solution

The duty of heat transfer fluids in enhancing power transfer is pivotal for attaining effective thermal management across different commercial fields. These fluids help with smooth heat exchange, making certain processes operate within ideal temperature level arrays and mitigating the threat of getting too hot. Their option, based on factors like viscosity and thermal stability, directly influences the effectiveness and sustainability of a system. Nonetheless, the intricacies of choosing the right fluid are typically undervalued. What are the essential factors to consider for this option, and just how do they influence both financial performance and ecological responsibility in industrial applications?

Function in Thermal Administration

Warm transfer fluids play an important function in thermal management by successfully managing temperature levels in different industrial processes and systems. These specialized fluids facilitate the transfer of warmth in between different parts, ensuring optimal operating problems and avoiding getting too hot. By keeping precise temperature level control, warm transfer liquids make it possible for sectors such as chemical production, oil and gas, and power generation to operate securely and efficiently.

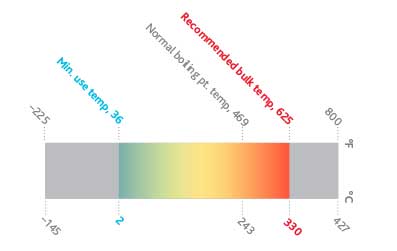

The selection of an appropriate warm transfer liquid relies on a number of aspects, including thermal stability, warmth capability, and viscosity. High thermal security makes sure that the liquid can endure extreme temperature levels without breaking down, while a high heat ability enables it to soak up and launch substantial quantities of warm - heat transfer fluid. Reduced viscosity reduces the power required for pumping, adding to total system effectiveness

Furthermore, warmth transfer fluids are indispensable in applications like refrigeration, where they assist absorb and dissipate warm throughout the cooling cycle. In solar thermal power systems, these fluids capture and transportation solar heat to create power or offer warm water. Their versatility to diverse operating conditions and capability to keep constant thermal efficiency underscore their value in industrial thermal administration, facilitating operational connection and enhancing precaution.

Enhancing System Effectiveness

To optimize the benefits of thermal monitoring, enhancing system efficiency with the critical usage of warmth transfer liquids is paramount. By maintaining optimum temperature level levels, warm transfer liquids help guarantee that systems operate within their created criteria, therefore preventing overheating and minimizing the threat of part failing.

Sorts Of Warm Transfer Fluids

The diversity of warm transfer fluids underscores their important role in a range of industrial applications, each tailored to fulfill details thermal administration needs. These liquids promote effective energy transfer and are chosen based on key residential properties such as thermal security, viscosity, and warmth capacity. The primary kinds consist of water, glycol options, oils, and synthetics, each offering unique advantages.

Water is the most common warmth transfer tool due to its high details warm ability and reduced cost. Mineral oils are preferred for their thermal security and non-corrosive nature, making them ideal for high-temperature applications.

These fluids guarantee remarkable efficiency in systems where standard liquids may stop working. The option of a check this heat transfer fluid is important, as it affects system performance, safety and security, and long life.

Environmental and Economic Conveniences

Making use of the ideal heat transfer liquids provides you could try here significant environmental and economic benefits for industrial procedures. Ecologically pleasant warm transfer fluids, often eco-friendly and non-toxic, minimize the danger of soil and water contamination in the occasion of leaks or spills, thus protecting environments and complying with rigorous ecological regulations.

Financially, the right warmth transfer liquid can dramatically minimize operational expenses. Fluids with prolonged lifecycle performance decrease the frequency of replacements and upkeep, lowering downtime and linked expenses. Generally, the calculated use of optimal heat transfer liquids sustains lasting economic growth and ecological stewardship.

Choosing the Right Liquid

Just how does one navigate the complicated procedure of choosing the best warmth transfer fluid for industrial applications? Thermal security ensures the fluid can hold up against high temperatures without breaking down, while compatibility protects against corrosion or various other harmful responses with system parts.

Additionally, the fluid's warmth ability and thickness are critical. A high warmth ability permits the fluid to absorb and transfer even more power, improving effectiveness.

Verdict

The calculated selection and application of have a peek at these guys warmth transfer fluids are basic to maximizing energy transfer throughout various systems. By making certain high thermal stability and ability, these fluids supply accurate temperature level control and improve overall system efficiency.